Mayco’s Stoneware Specialty glazes were developed for special effects and surface depth.

Cone 6 chips have been fired flat in oxidation on white stoneware body.

Cone 10 chips have been fired flat in reduction on white stoneware body.

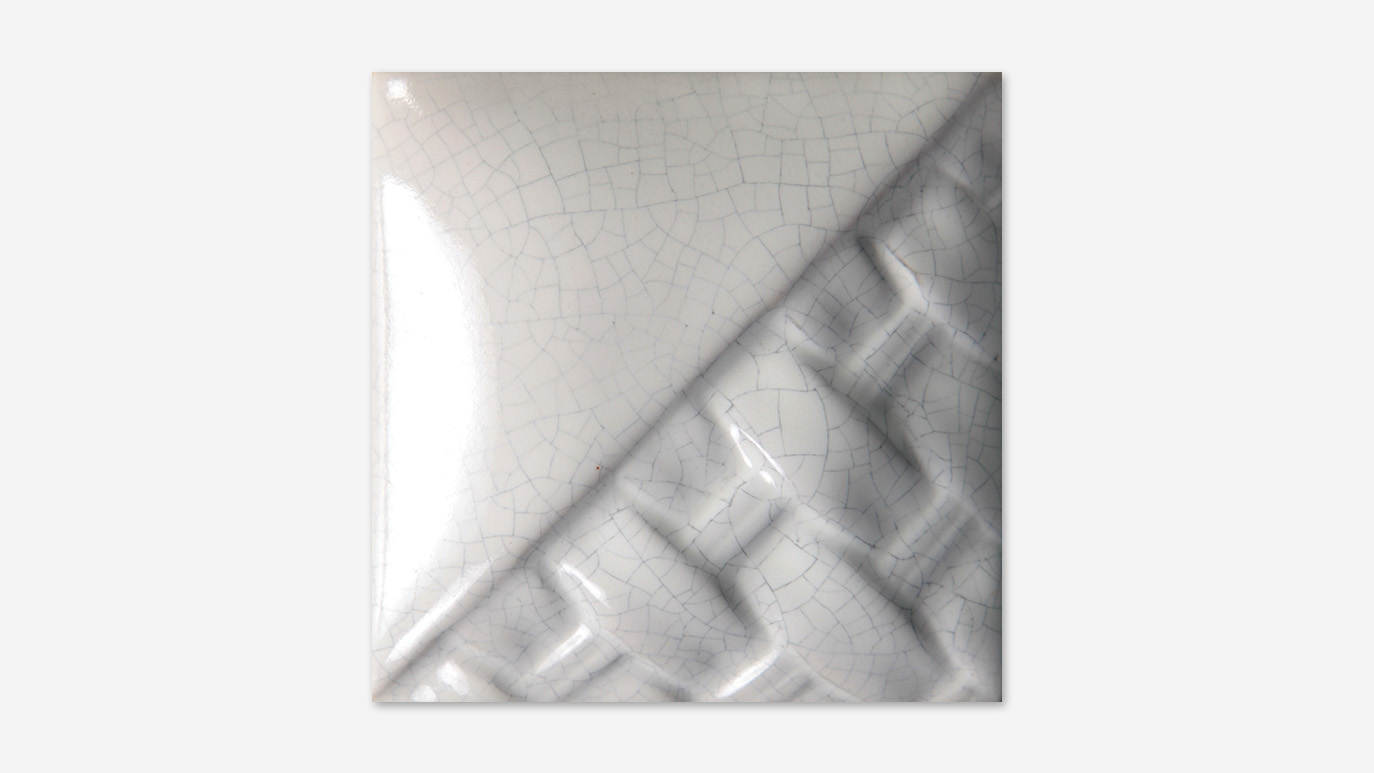

Magma and Mudcrack create a raised surface texture that adds tactility to the decoration. Crackle White and Crackle Matte Clear create a crackled pattern that has traditionally been used to create a vintage or antique appeal.

White Mudcrack and Black Mudcrack were developed to create a highly-texture raised and cracked surface. The thicker the application, the more textured the surface. Mudcrack can be directly applied to bisqueware or in combination with other mid-range glazes.

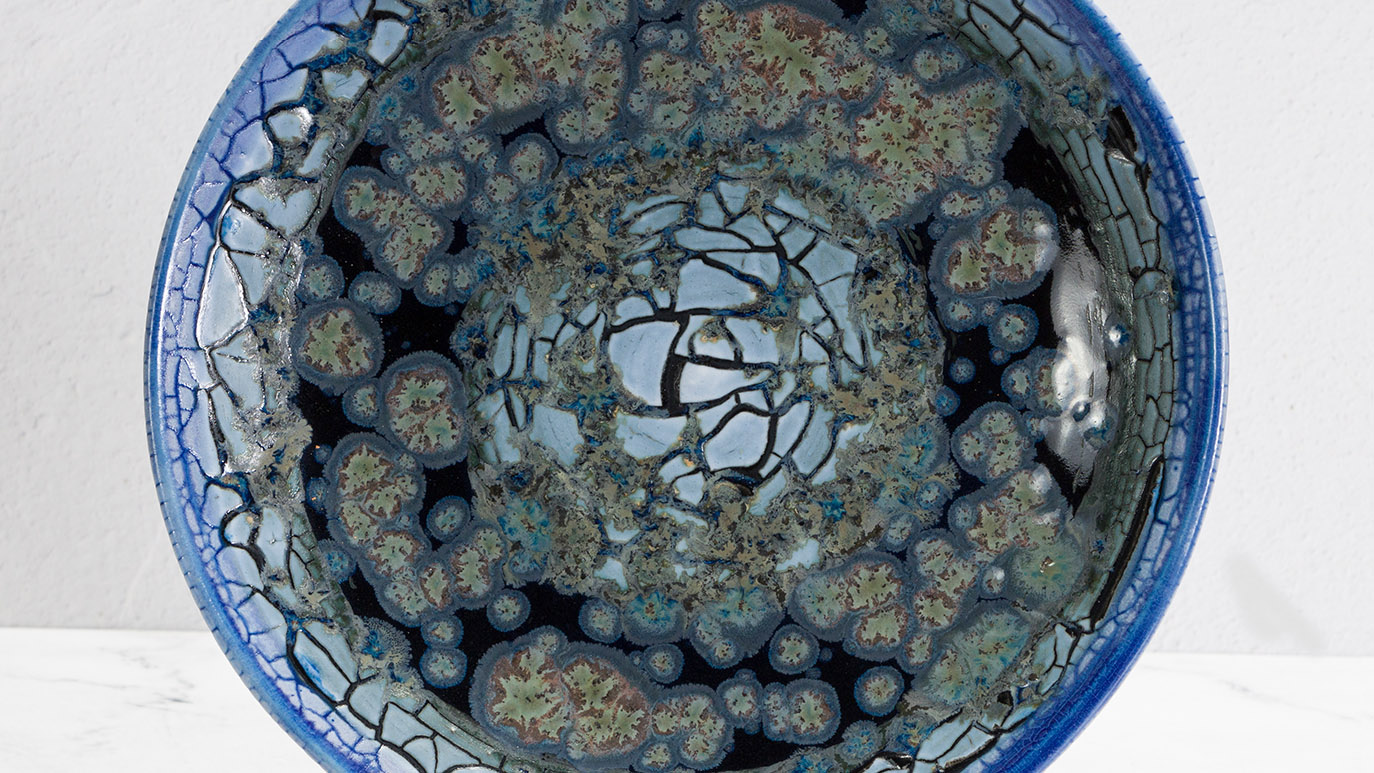

Light Magma and Dark Magma were developed to create a rough, cratered surface. The thicker the application, the more textured the surface will be. Magma can be directly applied to bisqueware or in combination with other mid-range glazes.

Crackle White is a bright white gloss glaze that develops a fine crackle pattern at mid-range firing temperatures. To highlight the crackle pattern, after firing, wipe black acrylic or ink over the ware and wipe off, allowing the ink to fill the cracks.

Crackle Matte Clear was developed for mid-range firing temperatures where a fine crackle pattern will develop with 2-3 coats. To highlight the crackle pattern, after firing, wipe black acrylic or ink over the ware and wipe off, allowing the ink to fill the cracks.

Mudcrack: Shake vigorously upon opening. Continue to shake and stir to increase fluidity to the consistency of cream. For shown chip results, apply directly to bisqueware. Apply 2-3 coats. Allow glaze to semi-dry between coats. The thicker the application, the more textured the surface will be. If the glaze does not crack on the piece before firing, it will not crack after firing. Due to the surface texture, we recommend that these glazes only be used on decorative surfaces.

Magma: Shake and stir well. For shown chip results, apply directly to bisqueware. Apply 2-3 coats. Allow glaze to semi-dry between coats. The thicker the application, the more textured the surface will be. A thicker application can be achieved by blotting or dotting the glaze onto the piece. Light Magma does not crater as much as the Dark Magma. We suggest using up to 5 coats to increase Light Magma texture. Can be applied with slip trailer. Due to the surface texture, we recommend that these glazes only be used on decorative surfaces. You may experience slight crumbling.

Crackle White: Stir well and apply to 3 coats on soft-fired bisque Allow each coat to dry before applying the next coat. Fire from cone 5/6-10. To highlight the crackle pattern, after firing, wipe black acrylic or ink over the ware and wipe off, allowing the ink to fill the cracks.

Crackle Matte Clear: Stir well. Apply to soft-fired bisque (cone 04/06). Apply one coat if dipping; 2+ coats if brushing. Allow to dry and fire to cone 5/6. To highlight the crackle pattern, after firing, wipe black acrylic or ink over the ware and wipe off, allowing the ink to fill the cracks.

Dry mix products: Always wear a NIOSH approved respirator when handling dry glazes. Gently tumble unopened bag to redistribute materials. Sieving is not necessary. Mix one 5lb bag of dry material into 4-5 pints of water. Stir thoroughly with a wood paddle, stick or drill with mixing attachment. We recommend using 15lb of dry glaze to start a 3 gallon bucket and 25lb to start a 5 gallon bucket. Add additional water until desired specific gravity is reached. Our recommended Specific Gravity is in the range of 1.47 to 1.51. Stir well before each use. Immerse the ware for 1-2 seconds. We suggest using dipping tongs. One dip of Mayco Dry is equivalent to 3 coats. Shake excess glaze off gently. Allow the glaze to dry before applying additional coats if desired. Fire from cone 5/6-10. Tip: Save your bag or log the lot number for if you have any questions for our technical team. Tip: Apply AC-302 Wax Resist to the bottom for easy dry foot clean-up.

Mudcrack, Magma, Crackle White and Crackle Matte Clear glazes have been certified as AP Non-Toxic, safe for use by artists of all ages when used according to manufacturer’s directions. However, they are not recommended for dinnerware due to the durability of the fired glaze. Some glazes, regardless of surface texture or porosity of underlying clay body, will be designated as not suitable for dinnerware as the fired glaze surface is not durable and can be impacted by contact with food or liquids. While it may not be harmful, it is certainly not desirable. Recommended for ornamental use only.

Mayco Specialty glazes are intended for use at cone 5/6, but many are also pleasing and stable at cone 10 oxidation, reduction or other alternative atmospheric firing conditions, such as wood, salt or raku. Cone 10 color performance can also be found on the left side of the stoneware glaze label. The choice of clay body, thickness of glaze application, firing process and temperature will affect the fired results. Due to variability, we recommend testing prior to application to artwork. View Mudcrack on different clay bodies here or Magma on different clay bodies here

Glazes will perform differently based on clay body used. We recommend testing prior to application to artwork.

Light Magma works well when layered with our Stoneware Gloss glazes (SW-501 through SW-510). There is a minimal shift in the texture and some color variation is achieved. Mudcrack glazes can also be layered with our Stoneware Gloss glazes (SW-501 through SW-510).

Both Magma and Mudcrack glazes work well with our Stoneware Washes (SW-301, SW-302, and SW-305) with some mild variation in texture.

Magma and Mudcrack can be used in combination with other Stoneware glazes to achieve different textures and effects. We recommend testing prior to use.

Magma glazes can be applied with a slip trailer for more controlled lines and patterns around your shape.

We offer both brushing formulations of our Mudcrack glazes. The results for each glaze are very dependent upon the application. The amount of texture and cracking that is produced with White and Black Mudcrack is directly a result of how thick the glaze is applied. A thinner application will result in a smoother surface with very fine cracks. A thicker application will result in larger cracks and more tactile texture.

When applying the glaze, pay close attention to the glaze performance while it is drying. If you only apply one coat, but the glaze is getting large cracks and is pulling up when drying, do not apply more glaze! Too thick of an application can result in your glaze cracking and pulling off your piece. As the glaze is drying you do want to see some cracking, but not to the point that the edges are curling up. If you don’t see any cracking, apply more glaze, but be vigilant during the application and drying process.

We offer both brushing and dipping formulations of our Magma glazes. The amount of dimension and cratering created with these glazes is directly a result of how thick the glaze is applied. A thinner application will produce a less dimensional surface, but there will be minimal cratering. It will have more of a sandpaper feel. A thicker application will produce a more dimensional and cratered surface.

Our Dark Magma glaze tends to produce more cratering than our Light Magma. To achieve similar results with both glazes + 1 or 2 coats to the Light Magma.

Our Mudcrack glazes tend to become thick and gelatinous as they sit. Agitate the glaze vigorously to reconstitute the glaze to a brushable fluidity. Add water if necessary. For dipping glaze, mix before dipping as you usually would.

All of Mayco’s Stoneware glazes are both Food Safe when used according to manufacturer’s directions and Dinnerware Safe with the exception of SW-132 Mirror Black, SW-182 Antique Brass, our Stoneware Texture glazes (SW-403 through SW-406), and our Stoneware Washes when used alone (SW-301 through SW-305). There is a factor of personal discretion when considering the use of any glaze on a surface that comes in contact with food. Some factors such as clay body, firing temperature, firing atmosphere, and the layering of glazes also contribute to the suitability of a ware for dinnerware use. It is the responsibility of the customer to practice practical consideration of these factors and observe how they affect the final fired surface. For more information about Food Safe and Dinnerware Safe guidelines check here:

Magma glazes tend to eat up pigment of mason stains and underglazes. Light Magma works well when layered with our Stoneware Gloss glazes (SW-501 through SW-510). There is a minimal shift in the texture and some color variation is achieved.

Mudcrack glazes produce a very fragile and dry surface when layered with underglazes and don’t take well to mason stains. These glazes can also be layered with our Stoneware Gloss glazes (SW-501 through SW-510)

Both Magma and Mudcrack glazes work well with our Stoneware Washes (SW-301, SW-302, and SW-305) with some mild variation in texture.

Yes the can. Some will change significantly, some not much. Best we can do is provide this visual gallery and let you see what each glaze can do at cone 10 reduction. Cone 10 color performance can also be found on the left side of the stoneware glaze label. The choice of clay body, thickness of glaze application, firing process and temperature will affect the fired results. Due to variability, we recommend testing prior to application to artwork.

All of our Stoneware Specialty glazes can be layered with other glazes. There will be a reasonable variance in the finish, color, and texture. As always, we recommend testing glazes with your preferred application, clay body, and firing temperature.

As with all of Mayco’s Stoneware glazes, they have a firing range from cone 5 to cone 10. The samples we showcase in our promotional material and literature are glazed on a white clay body and fired to cone 6 unless otherwise noted. Expect some variation in the results depending on the glaze thickness, clay body, firing atmosphere, and firing temperature. We have cone 10 reduction results on our website, in our Stoneware Brochure, and listed on the label. We recommend leaving extra clearance around pieces with Dark Magma in the kiln. Our Dark Magma tends to fume in the kiln and can discolor nearby wares. The thicker the glaze application, the more likely it is to fume.

Practice caution when handling and loading a piece with completely dry Mudcrack glaze. The surface will crack as it dries and becomes very fragile. It is helpful to handle the piece while the glaze is still a bit damp to preserve the surface. If your Mudcrack is applied too thick, it may pop off during the firing. You can tell if the Mudcrack is applied too thick if it is curling up and popping off as it dries.

Our manufacturing process includes ball milling to very precise particles sizes. All you need to do to use our dry-mix glazes is add water, slake, stir and DIP. You’ll love the sheeting action when dipping and be pleased to find that our dry-mix glazes will not settle out in your storage bucket.