Inspired by aspects of nature, Elements™ and Elements™ Chunkies produce lush, organic, and earthy hues.

Cone 06 chips have been fired flat in oxidation on white earthenware body.

Cone 6 chips have been fired flat in oxidation on white stoneware body.

Cone 10 chips have been fired flat in reduction on white stoneware body.

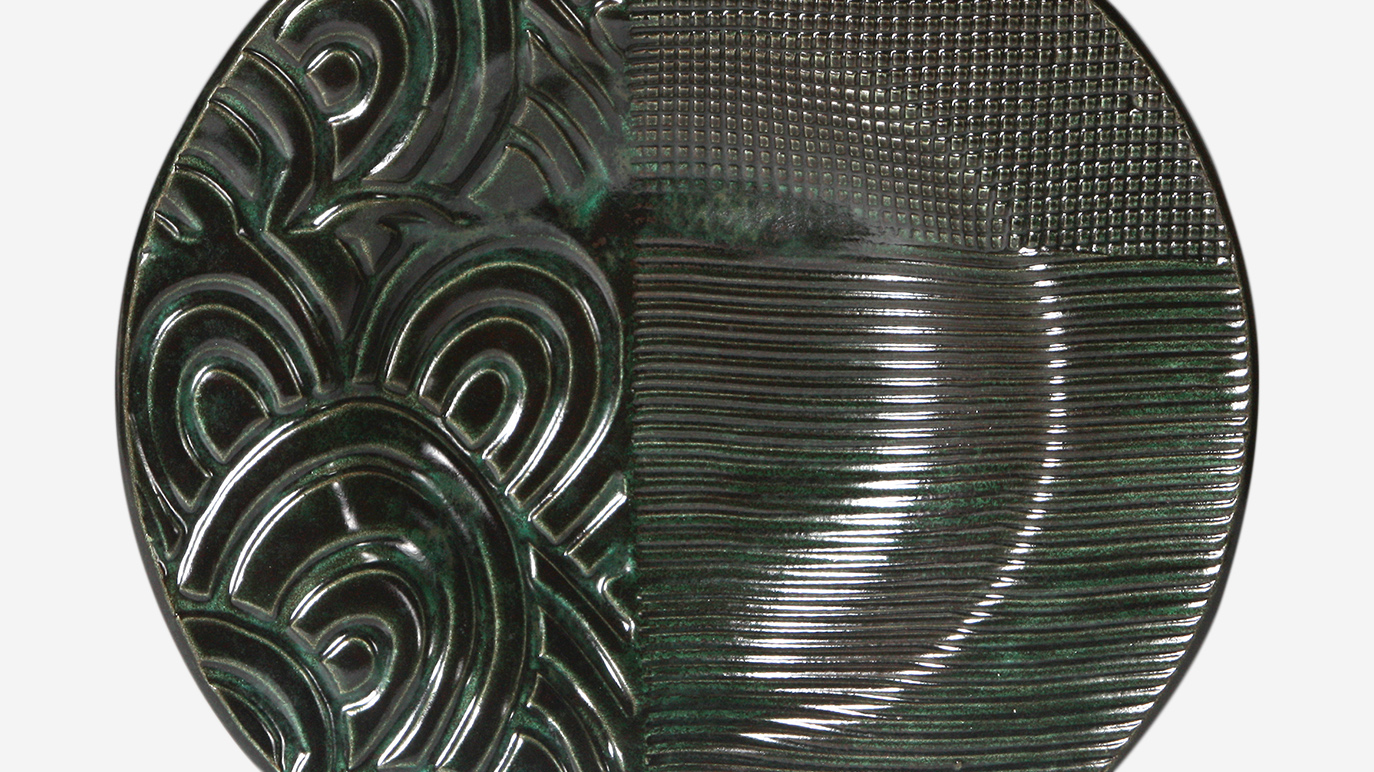

Designed to simulate the aesthetic, movement and interest of mid-range and high fire glazes in a cone 06/05 oxidation kiln firing, Elements™ and Elements™ Chunkies give artists a wide variety of options in one product, as glaze application, firing temperature and shape will influence the outcome of finished work. Elements™ are a two-tone glaze with a main color and a secondary color called a float. When Elements™ are applied to detail pieces, the float color will appear in the crevices. Application and firing will also affect the outcome of main color or float.

Elements™ and Elements™ Chunkies vary from gloss to matte, with subtle variations occurring in each color.

Shake for five to six seconds before use. Dispense glaze onto a palette (tile, plate, etc.) and apply with a soft brush or decorating accessory of choice (sponge, stamp, etc.). Dipping your brush directly into the jar may contaminate the jar’s contents, especially if you are using other glazes. Apply three to four coats to your piece. Elements™ glazes were designed to mature at a shelf cone 06 (999° C or 1830º F). When applying them over a large surface area, we recommend a broad, soft fan brush.

Moisten the brush with water first. The brush fully saturated (loaded) and each coat applied in the same direction. When the wet look has gone from the first coat, you may apply the next coat of glaze. Be sure the glaze has dried thoroughly prior to firing. A medium ramp/firing rate is recommended (250°F per hour) at shelf cone 06. Elements™ can be fired at higher temperatures but will change in appearance. We recommend testing prior to use.

Some Elements™ glazes are not to be recommended for dinnerware produced from low fire earthenware clay bodies as these glazes can exhibit surface textures such as cracks and crevices. While the glazed surface may pass lead & cadmium leach tests, and therefore legally considered Food Safe, attempts to adequately clean the textured surface may cause the underlying porous ware to absorb water and fail. Elements™ glazes may be considered dinnerware safe if surface texture is eliminated when firing to mid-range or high fire temperatures. The key is recommended usage for low fire (earthenware cone 05/06) dinnerware. Glazes with surface texture applied to vitrified clay bodies do not have the same concern.

View the complete list of ACMI & Dinnerware Safe ratings for Elements™.

Elements™ are stunning on their own. Vary the number of coats and ware used to achieve different variations of one glaze.

Elements™ may be used to create designs or applied as a natural backdrop to your artwork.

Layer Elements™ colors when applying or use in combination with other glazes, such as Elements™ Chunkies, Stroke & Coat®, Foundations®, Jungle Gems™, or Stoneware to create unique looks.

Designer Liner designs will not move or blend when used over non-moving Elements™ glazes.

Pottery Cascade™ act as a flux with Elements™ to create movement in the colors. Great visual effects are created when added under, over or in-between Elements™ or Elements™ Chunkies. Pottery Cascades are perfect for the low fire designer seeking to create the looks achieved at higher temperatures. Variability ensures that no two designs will be exactly alike.

While formulated for cone 06/05 use, many of the Elements™ and Elements™ Chunkies glazes perform beautifully at higher temperatures. Refer to the individual color label for cone 6 firing performances. As Elements™ tend to flow at higher temperatures, the orientation at which your glazed ware is fired (flat vs vertical) can greatly impact the look. Due to the movement of the glaze, we recommend limiting the glaze on the bottom third of a vertical piece to avoid running off the ware. We recommend testing to determine color, surface characteristics and movement prior to use.

Apply to properly fired shelf cone 04 bisque. Use a soft fan or glaze brush, depending on the area and surface to be covered. Generally, three- four coats of glaze are recommended. However, applying four coats will produce a totally different look. For a different effect, brush on three coats and apply a final fourth coat using a silk or sea wool sponge. An uneven glaze application and the ware’s shape and surface (plain or embossed) will also affect the look of the glaze. Painting in a criss-cross fashion will effect the fired finish.

When using Elements™ on the outside of a vase or cylinder, we recommend using Foundations® opaque, Foundations® sheer, or a clear glaze on the inside. Using Stroke & Coat™ may cause the piece to crack due to the stiffness of the glaze.

When Elements™ are re-fired to lower lustre temperatures (shelf cone 018-020), the original glaze color changes. If this is not the desired effect you will not want to apply lustres over them. However, you may find the re-fired finishes to be desirable. Our advice is to experiment and make test samples using lustres with the specific Element™ glaze with which you are using.

If you choose to apply the two glazes, keep in mind that there will be chemical interaction between the glazes and Stroke & Coat® may change colors. Additionally, Elements® glazes move, so a design may lose the defintion. It is recommended to test.

Both Elements™ and Elements™ Chunkies have the same base glaze formula but the and Elements™ Chunkies contain crystals that will expand on the surface during firing.

Many Elements™ create beautiful effects when used with stoneware in a cone 6 firing environment. Cone 6 color results can be found on the left-hand side of the label giving a description of the fired results at cone 6. Care must be used in the application as Elements will be quite fluid and move during the firing process. Keep away from the bottom of ware by tapering toward the bottom of the piece or create a natural stop with another glaze. Many of the Elements™ produce interesting effects at cone 6 but will change color. We recommend testing to determine color, surface characteristics, and movement prior to use. Testing should also be done to determine if this glaze fits the cone 6 clay body you are using.