Stroke & Coat® is the industry’s most versatile glaze. It can be applied on wet clay, earthenware bisque, or stoneware bisque, fired from cone 06 to cone 10, in oxidation or reduction, and used in every decorative way imaginable.

Cone 06 chips have been fired flat in oxidation on white earthenware body.

Cone 6 chips have been fired flat in oxidation on white stoneware body.

Cone 10 chips have been fired flat in reduction on white stoneware body.

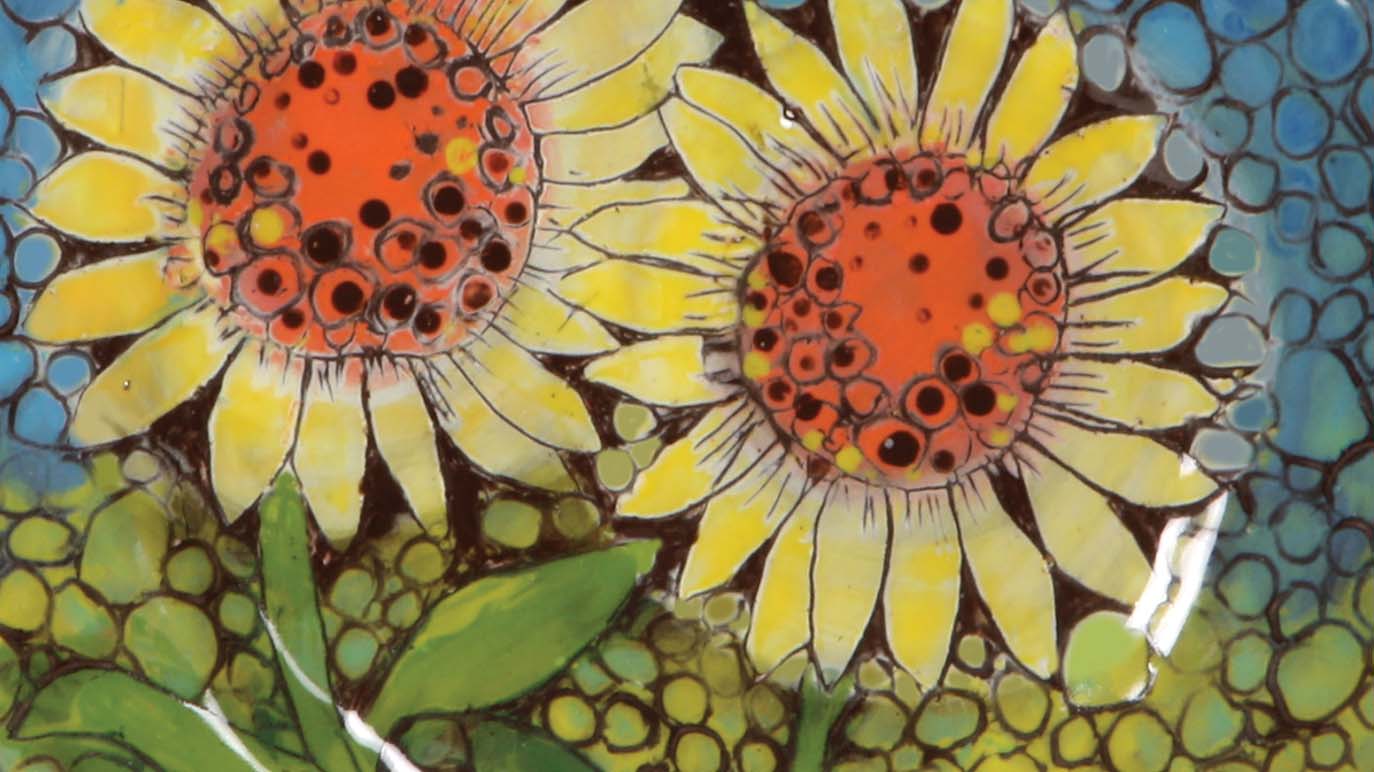

Stroke & Coat® is a heavily pigmented, viscous glaze line that can be used for brush strokes or opaque coverage. Use these glazes to create intricate, detailed designs and butt up to one another without colors moving. When used in a majolica process, Stroke & Coat® will not move nor blend with the colors beneath. Stroke & Coat® colors are intermixable, allowing artists to create custom shades. Thin with water to create a “wash” or watercolor style of design. Because the liquid color is consistent with the fired color, artists will have no trouble visualizing finished results as they create.

Stroke & Coat® can be the star of your work or play a supporting role to other glazes. Stroke & Coat® glazes are the ideal product of choice for studio, classroom, potter or fine artist.

One coat of Mayco Stroke & Coat® will create a translucent finish with subsequent coats adding opacity. We suggest 2-3 coats for full opacity and all over coverage. Let dry between coats. Stroke & Coat® glazes will fire to a gloss finish without clear glaze. However, if desired, a clear glaze (such as NT-CLR Clear One Dipping Glaze or S-2101 Crystal Clear Brushing) can be added. For application on wet or leatherhard clay and firing to cone 04, colors will retain their vibrancy with huge time savings. We recommend leaving an area unglazed, such as the back or bottom of the unfired piece, to allow for out-gassing of the clay during the single-firing process. Limit glazes to 2 coats including design work.

Stroke & Coat® glazes are certified AP Non-Toxic, Food Safe and Dinnerware Safe when used according to manufacturer’s directions.

Layer Stroke & Coat® colors when applying or use in combination with other glazes, such as Foundations®, Jungle Gems™, Elements™ & Elements™ Chunkies, Designer Liner, Stoneware, or Cobblestones to create unique looks. When used in a majolica technique, Stroke & Coat® will not move or blend with surrounding colors.

The Stroke & Coat® red hues are the best on the market. SC-73 Candy Apple Red, SC-74 Hot Tamale, and SC-87 Ruby Slippers are easy to use and fire red every time with no special application or extra attention during firing. Great for kids and students, and perfect for the potter looking for red coloring up to cone 10.

Lighter colors can be used over dark colors, remaining bright and opaque, and will not blend with the colors underneath.

Apply Stroke & Coat glazes directly on wet or leatherhard clay, allow to dry, and fire to cone 04. Colors remain glossy and vibrant and save you time by removing the bisque fire step! As an alternative, you could also use Stroke & Coat® in a wash technique, add a coat of clear glaze and fire to cone 04. For application on clay, limit glaze coverage to 2 coats including any design work. We recommend leaving an area unglazed, such as the back or bottom of the ware, to allow for out-gassing of water and organic materials during the firing process.

Stroke & Coat® will fire glossy without addition of a clear glaze. Clear glaze can be added if additional glossiness is desired or Stroke & Coats® glazes have not been applied in a consistent, overall coverage onto unglazed ware.

”To scratch” in Italian, sgraffito is produced by applying layers of Stroke & Coat® and carving through the glaze to create depth and add contrast to your designs. An impactful and dramatic way to use Stroke & Coat® on your ceramics or clay surface.

One coat of Stroke & Coat® glazes result in a translucent effect with additional coats adding opacity. Stroke & Coat® glazes are heavily pigmented and will not streak, no matter the number of coats.

Many Stroke & Coat® glazes perform well at mid-range (cone 5/6) and higher temperatures (cone 9/10). Darker colors such as red, orange, yellow, blue and green may darken compared to their cone 06 results. Lighter colors such as tan, purple and pink will fade. We recommend testing at your preferred firing temperature prior to use. Cone 6 performance is noted on each color’s label.

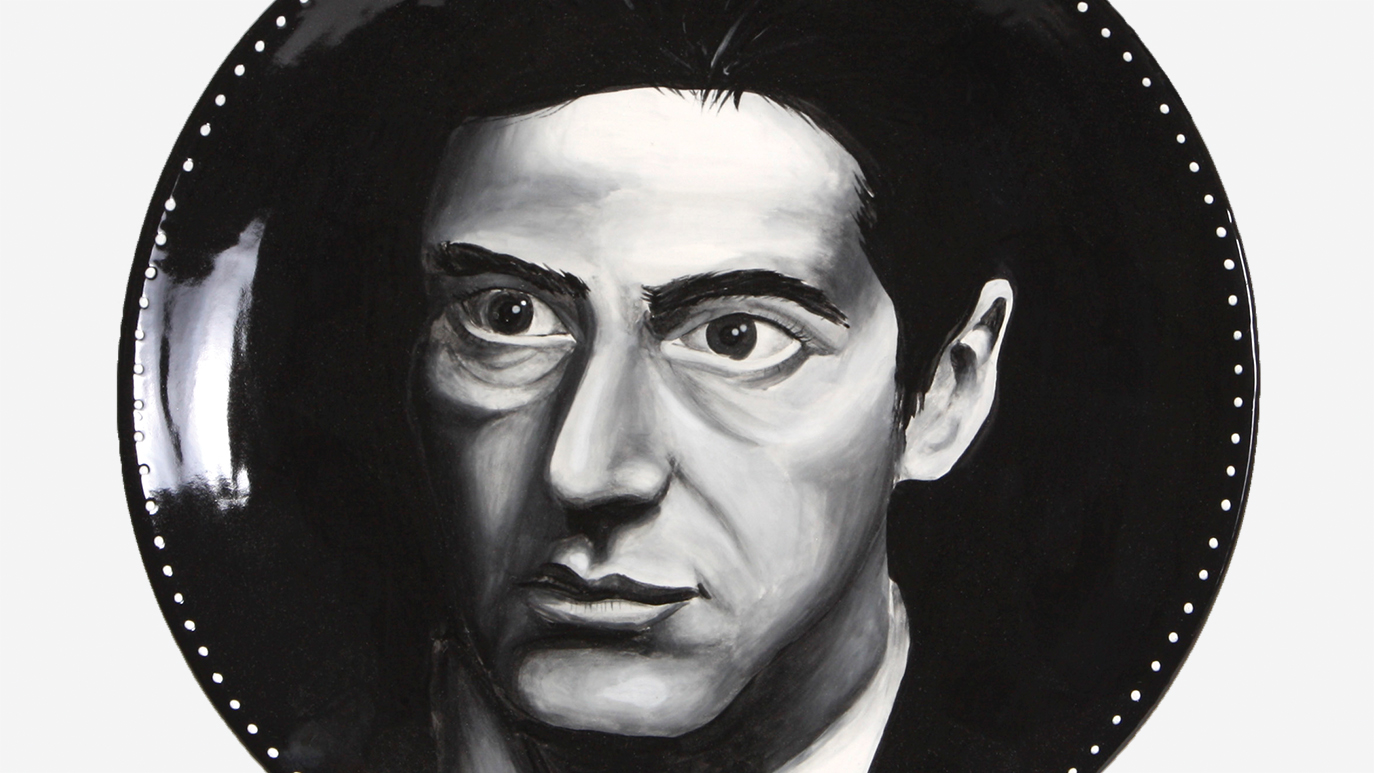

Much like using an oil or watercolor, Stroke & Coat® glazes can be used to create a life-like portrait or landscape, using rendering, shading, blending and other painting techniques to add dimension and a sense of realism to your work.

Paint intricate patterns as Stroke & Coat® glazes will not move or bleed into surrounding colors. Double load color onto brushes or use specialty brushes such as CB-106 Script Liner or CB-202 #2 Detail Liner to generate various shades of color and add dimension.

Some Stroke & Coat® colors will be more transparent at mid-range and higher firings. However, this can be a benefit to allow an underlying clay body to show through, such as on a speckled clay body, and enhance texture on your ware.

Stroke & Coat® fires glossy without clear glaze. Clear can be added if not applied in consistent overall coverage. Adding clear glaze to cone 5 and higher can affect the color outcome and will cause designs to move and blur. We recommend Mayco SW001 Stoneware Clear or SW004 Zinc Free Clear in brushing or dipping.

Stroke & Coat® can be the star of your work in all over coverage, a liner glaze for the inside of your ware, or play a supporting role to other glazes. Use Stroke & Coat® in combination with other Mayco products at cone 5/6 for a variety of effects.

Stroke & Coat® works beautifully when applied to different clay bodies including wet clay, greenware, or soft fired stoneware bisque. Application to darker or speckled bodies may cause a shift in color results. Testing is recommended.

With ease of use, Stroke & Coat® glazes allow for a wide array of design techniques at cone 5/6 including sgraffito, stamping, slip trailing, and the popular peacock technique where pops of color move and create dramatic effects using different combinations of Flux and Stoneware glazes.

When used as detail in design, Stroke & Coat® will often blur or soften. While they can be used in design, they may not produce crisp design work when layered with other products. Read more for tips on how to achieve crisp designs using Stroke & Coat®.

Stroke & Coat® fires to a gloss finish and does not require a clear glaze. Clear glaze may be used to enhance the glossiness of the fired finish. Apply the clear glaze according to manufacturer’s directions over the unfired Stroke & Coat® and fire once. Note: The amount of non-toxic glaze deposited can affect the fired results. If too much glaze and clear glaze is applied you may experiences dull or “milky” fired finishes. If this occurs, adjust the number of glaze layers applied, lighten the amount of glaze on your brush, etc. – whatever is needed to reduce the total amount of glaze placed on the ware. For pieces already fired – you may improve the fired finish by re-firing either at shelf cone 06 or cone 05 and adding a hold/soak time at the end of the firing cycle (10-15 minutes).

All Stroke & Coat® colors are luster compatible, even with clear glaze is applied over the top.

Stroke & Coat® will remain moderately dimensional when applied in a concentrated area. To create a raised line with a brush: layer 4 to 6 coats, allowing each coat to dry before applying the next. You may also use a detailer bottle or slip trailer to create raised lines: apply 2-3 layers, again allowing each layer to dry between applications.

Gases and moisture will escape from the greenware during firing, so it is best to leave a portion of the ware unglazed – for example: the back of a tile, the foot of a vessel – to avoid pin-holing or craters. If you do completely glaze a greenware piece you may also experience a dulling of the gloss finish. If this occurs, you can apply a clear glaze and re-fire to cone 06 or cone 05 to get a gloss finish. We suggest limiting glazes to 2 coats including design work. Always test to see if Stroke & Coat® will work on your specific greenware project.

Tips for Design Work

Color

Firing hotter may alter the color. While most colors have little change, some, such as pinks and purples often shift in color or fade. Make sure to check MaycoColors.com, chip charts, brochures, or labels for cone 6 results before use.

Texture

Red and orange Stroke & Coat® colors may produce an orange-peel texture when fired to cone 5/ 6 and up. We find the finish is improved when thinned with water or applying only 2 coats. The texture can also improve when combined with Stoneware

glazes.

Go Hotter

Stroke & Coat® can take the heat with many colors maintaining their vibrancy at cone 10 oxidation, reduction or other alternative atmospheric firing conditions, such as wood, salt or raku. Click on Color Swatches at the top of the page to see cone 10 reduction samples.

Stroke & Coat® glazes are compatible with all Mayco glazes and with many alternative brands of glazes. It is not recommended to design on top of the fluid, moving glazes, such as Jungle Gems™, Pottery Cascades™ or Elements™, as then work may become distorted.

Stroke & Coat® is a heavy-bodied glaze that levels out and heals imperfections during the glaze application process. It can withstand over firing without fading and it is tolerant of many types of bisque and clay bodies. It is not fluid like many gloss glazes – it behaves more like a traditional underglaze as it “stays put” where it is applied when fired to low-fire temperatures. It’s like having 4 or 5 different glazes in one bottle – a glaze for bisque and clay.

Yes, Stroke & Coat® is intermixable, keep track of the quantities to be able to recreate or make a large enough batch to complete the project and Mayco recommends testing. It is perfect for creating your own color theory project.